Services

Well Engineering

This Page is under construction

Onshore Drilling

Through the effective utilisation of our resources, we are experts at providing the optimum level of support to match the specific requirements of each project. Whether it is a single engineer or a multi-disciplinary team, we have the capability and experience to deliver high quality, cost effective support for your short term or long-term requirements.

Our well services

Well Engineering: From discrete studies to entire field development planning and integrity.

Well Project Management: We can deliver any well related project either on an outsourced basis, or as part of your team.

Well Operator, Well Management : Responsibility for the monitoring and management of wells.

Well Abandonment: Abandonment methodology and design through to full project management.

Well Engineering Manpower: Providing qualified and competent personnel.

We have a deep technical capability covering all well engineering and project execution requirements. We have worked in all onshore and offshore environments, and many different types of projects. We design, plan, explore, drill, develop, test, complete, operate, maintain and abandon wells.

Mud Services

We dedicate ourselves to become a comprehensive drilling fluid services company which provide the technical service in India and geared to international practice. We can provide drilling fluid services for the rigs. We focus on drilling fluid additives research and supply, drilling & completion fluid technical services, waste management and solid control services.

We are developing cost effective mud engineering solutions for drilling complications like shale inhibition, abnormal pressure and temperature using both water and oil-based mud.

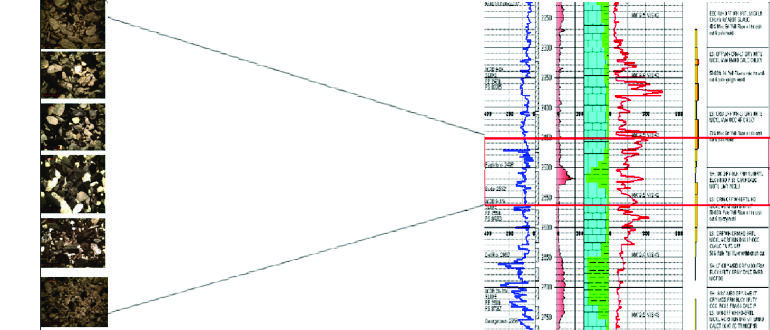

Mud Logging

Saihyandri Energy Services also provides mud logging services. Saihyandri Energy Services Mud Logging provides clients with real time drilling information that is useful with drilling exploration wells where decision making is essential to save costs.

Geological Functions

Services offered include geological and formation evaluation based on continuous cuttings description, fluorescence testing and analysis of Chromatograph and Total Gas readings. Monitoring of the drilling operation, detection and reaction to any critical changes in drilling parameters, thus facilitating early recognition of potential problems. Data acquisition, display, storage and processing information is instantly duplicated at the Driller’s monitor on the rig floor and in the Toolpusher’s or the company representative’s office.

Surface Data Measurement

Measurement and data recording include depth, bit location, rate of penetration, hookload, weight on bit, RPM, rotary torque, pump pressure, casing pressure, pump-strokes, pit volumes, flow rate, mud weight and mud temperature. Options include mud conductivity, pH and electromagnetic flow meter readings.

Gas Analysis

Gases are separated from the mud by a specially designed constant flow extractor placed at the shale shaker. The gas/air mixture is analysed by TCD-based Field Chromatograph or Total Gas equipment and more complex FID-based analysers.

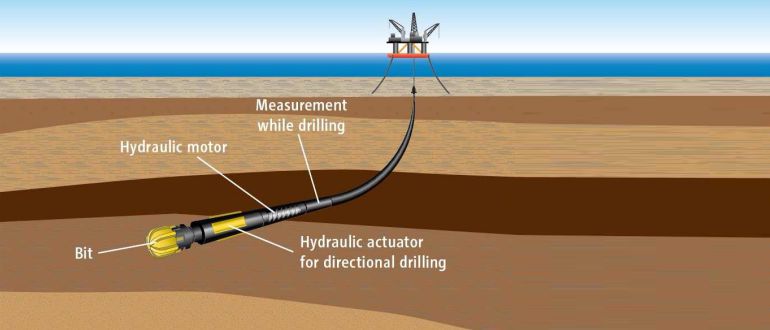

Directional Drilling

Saihyandri Energy Services is an Indian-based directional and horizontal drilling company that provides drilling and measurement while drilling services in the domestic market. With a highly experienced team, our personnel and directional drillers use the latest well-planning software, performance drilling equipment and sound drilling theory to help our clients reach their desired down hole target. Focused on building strong client relationships, our team’s wealth of knowledge allows us to drill for operators in both conventional and un-conventional oil and gas fields in many parts of India.

MWD Services

Measurement-while-drilling (MWD) services utilizing both the GE Pilot MWD and Tolteq TruCourse system. We own and operate systems capable of memory Gamma Ray values. All offered MWD systems are retrievable and can be reinserted to minimize lost in hole risk while some can operate in temperatures up to 347°F.

Well Cementing And Simulation

Our Services Include

Lab testing

Engineering

Field operation

Cement failure investigation

Lab testing : Cement Performance Testing

Cement performance testing include confirmation testing and qualification testing. Independent testing of cement slurry designs identifies potential issues pre-job, validates the repeatability of test results, and ensures that both client and regulatory design specifications are met.

Our performance testing services have been used by clients to evaluate new cement service providers, spot-check current field slurry designs for quality control, and ensure regulatory compliance. The process involves testing cement blends, ensuring they meet minimum requirements and recommending any necessary design changes through a detailed report to the operator. The laboratory tests performed on the samples include thickening time, compressive strength, rheology, fluid loss, and free fluid. Cement performance testing can be combined with bulk plant auditing and the use of onsite field advisors for a complete evaluation.

Analytical Lab Testing

Saihyandri Energy Services provides analytical testing services for chemical characterization to support stimulation and completions operations.

Chemical Quality Control

Chemical quality control testing is also available at Saihyandri Energy Services to ensure that chemical performance meets required product specifications.

Stimulation Tests

Saihyandri Energy Services offers basic and advanced fracture fluid testing. Services offered include both design work and general fluid testing.

Engineering

Bond Log Analysis

Saihyandri Energy Services can provide expert review, analysis, and recommendations on cement evaluation via logs. Their experience and expertise provide focused cementing evaluations to give operators confidence and expert advice on zonal isolation and squeeze options. Conventional CBL logs, segmented logs, attenuation logs, and ultrasonic logs can be evaluated.

Modeling/Simulation

At Saihyandri Energy Services, primary and remedial cementing receive comprehensive technical support, which include engineering design and computer modelling to ensure that client requirements are met.

Cementing Design Engineering Review

Saihyandri Energy Services provides a line-by-line analysis of your engineered cementing program and laboratory results to ensure that the software, testing parameters, and overall basis of design align with actual well conditions by incorporating industry-best practices that are known to correlate with object success.

The review include:

Most recent well conditions

Lithology

Pore pressure/fracture gradients (planned and confirmed through drilling)

Bottomhole static and circulating temperature

Circulating density and pressure

Mud removal performance and sandoff recommendations

Slurry performance acceptance criteria

Any other notable concerns

*All information provided by operator will be referenced in the engineering review, it is understood that in some conditions, all variables are not known/confirmed and reasonable industry accepted estimations will be used in their absence.

Well-Site Operation Experts

A good cement system designed in the lab will only work in the field if pumping operations are executed according to design. CSI wellsite operations experts go to the location and monitor cement operations to verify that best practices are being followed throughout the job. These experts will review the job proposal and test results, performing all cementing volume calculations prior to beginning the cement job. They will compare results with the cementing crew and company man to ensure that all are in agreement and that sufficient cement and additives are on location for the job. Prior to the job, field advisors will verify that the cement lines are rigged up correctly and attend the pre-job safety meeting to ensure that all job parameters and safety precautions are discussed, providing additional input as necessary. During the cement job, the expert will monitor the cement crew to verify that the spacer and cement are pumped as designed, the correct displacement is pumped, the cement plugs are launched at the appropriate time, and best practices are followed by the crew. Onsite recommendations for improvement can be provided if requested by the client.

Bulk Plant Facilities and Equipment Auditing

Onsite quality control in the bulk plant ensures that appropriate procedures are being followed and that client quality standards are met. Saihyandri Energy Services provides onsite cementing audit services for bulk facilities and equipment.

Related services include:

Lab testing

Cement testing

Engineering

Bond log analysis

Field operations

Well-site operations expert

Chemical Product Development

Saihyandri Energy Services works with clients to develop, evaluate, and validate new products for oilfield applications.

Well Intervention Services-Coiled Tubing, Nitrogen, Slick Line

Saihyandri energy services provides fully integrated Coil Tubing, Nitrogen and Pumping Services, together with the required engineering, laboratory services and supply of chemicals.

Coiled Tubing Services

Coiled Tubing Assisted Operations include:

Stimulation treatments

Spotting cement plugs

Squeezing operations for zone isolation/water or gas shut off

Fishing/milling operations

Well killing

Sand cleanouts

Kicking off wells with Nitrogen

Nitrogen Services

These services provide support for our Coiled Tubing operations. Units are trailer mounted, each having 4000 gals of LN2 capacity. Nitrogen pumping packages are also used for stand-alone operations for carrying out the following activities:

Foam clean-outs

Co-mingled, nitrified fluids

Purging pipelines and facilities

Inert Operations

Drill-stem testing

Under-balanced perforating

Well displacements

Pressure testing

Laboratory Services

The Coil Tubing, Nitrogen and Pumping Services department also operates laboratory facilities, managed by qualified and experienced technicians, who carry out tests and analysis of well fluids and chemicals, for optimum job design and quality control purposes. Treatment formulations and troubleshooting are done here under our expert supervision. The department also provides portable type laboratories for field use. These are designed to easily locate on the onshore/offshore locations, as required.

Pumping Services

Pumping services provide support to Coiled Tubing and Nitrogen Services and also used as a stand alone service to our clients. Pumping units are both skid as well as truck mounted and supported with all the required field equipment, such as acid mixing and transport equipment. Pumping services are also supported by a stimulation laboratory.

Pumping services also include the following activities:

Acid Stimulation Treatments

Pressure Integrity Testing

Well Killing Operations

Pipeline Flushing/Testing

Scale Inhibition Treatments

Pressure Testing

Well displacement

Pump support for Coiled Tubing operations

Well workover and production consultation and services

We offer our onshore integrated workover services to local and international oil and gas companies primarily in India. In addition to performing remedial work on existing wells, our fleet provides completion services on the new production wells drilled by EDC.

A workover is the process of maintaining, repairing or enhancing production from a well through various means. Most workovers require the production tubing string to be pulled from the well by the workover rig in order to repair the defects that may be causing sub-optimal well production. The production tubing is inserted back into the well once the defects have been repaired. In some cases, a workover is performed in order to carry out hydrofracking and acidizing.

The following are common workover tasks that we perform.

- Subsurface pumping. Subsurface pumps are required in the vast majority of the onshore oil producing wells in India. These pumps have a finite life and are routinely replaced, on average, every 12 months

- Remedial cementing. Frequently, cementing operations are carried out on existing wells to shut off water or unwanted gas production.

- Tubing replacement. Most workovers require the production tubing string to be pulled from the well. As a result, production tubing needs to be replaced as part of the workover process.

- Well cleanout. This entails the removal of debris, sand, scale and organic materials from a well to improve the flow of hydrocarbons to the surface. Many reservoirs produce sand that is not carried to surface by the flow of hydrocarbons during production. The resulting accumulations can decrease production and are cleaned out periodically.

- Re-completion. Downhole completion hardware is exposed to materials such as corrosive water, sand, scale, tar and wax which can clog and damage equipment. Re-completing a well may mean extracting the hardware and repairing or replacing it, in part or in its entirety. Alternatively, as downhole well conditions change over time (as a result of increased levels of watercut, for example) or as technology improves, different tools may be used or artificial lift hardware may be employed (such as electrical submersible pumps). Wells are often re-completed in different zones to enhance production.

- Additional perforations or re-perforation. In certain oilfields it is possible to perforate additional intervals in hydrocarbon bearing reservoirs to increase production rates. In other reservoirs it may be possible to re-perforate an existing perforated interval that has become closed. New technologies also allow for deeper penetrating perforating charges Workover services are primarily contracted on a rate per hour basis.

Oil Field Equipment & Spares Trading

If you are looking for oilfield drilling equipment or drilling parts, you’ve come to the right place. Saihyandri Energy Services Oilfield Equipment is in the process of setting up a Trading Division for supply of equipment, parts and spares for the industry. Our personnel have extensive experience in this field so you can count on getting the precise equipment and part. Our supply network reaches multiple manufacturers and suppliers globally to source your requirement.

Saihyandri Energy Service Equipment Rental Division offers you a complete full cycle solution for all your equipment rental needs for downhole tools, tubular, tubular handling gears, pressure control equipment, fishing gears and any other rental requirement to your rig sight.

Drill Pipe

Drill Collars Slick, Drill Collars Spiral, Drill Collar Non-Magnetic, Drill Collar Flex…

Tubular Handling Equipment

Bowl & Slips, C Plates, Casing Tong, Circulating Fill-up Tool, Drift…

Downhole Tools

Casing Scraper, Circulating Subs, Crossover Subs, Cup Testers…

Pressure Control Equipment

Actuators ESD Valves & Control System, Annular & Diverter BOP…

Fishing Gears

Accelerators, Bumper Subs,Casing Cutters, Casing Rollers, Die Collars…

Surface Well Testing

Saihyandri Energy Services is an Indian company providing exploration and production well testing in the Indian sub-continent. The testing of oil and gas wells is an integral part of reservoir management for both new and mature oil/gas fields alike. We provide these services both onshore and offshore.

Saihyandri Energy Services offers state-of-the-art equipment packages for all surface applications, manned by highly qualified, trained and experienced professionals. These packages are often custom built to meet most application.

We have capability and equipment to test wells up to 15,000 Psi well bore pressure. Since the integrity of the data collected during well testing is very important, Saihyandri Energy Services uses state-of-the-art data acquisition techniques.

We also provide in-line sand management systems and services for post-frac clean ups. Coupled with modern Multi Phase Flow Meters, this makes a powerful tool when developing HP/HT gas/condensate reserves.

Developed equipment and techniques, aligned with international standards and world-best practices, makes it the preferred services provider in India with proven records in executing assigned jobs in an efficient, cost effective and timely manner.